Home » Product Catalogue » TRAILER AND BODY EQUIPMENT » TOW EYES AGRICULTURAL AND INDUSTRIAL » AL03196 40mm 120kN ROAD RATED

AL03196 40mm 120kN ROAD RATED

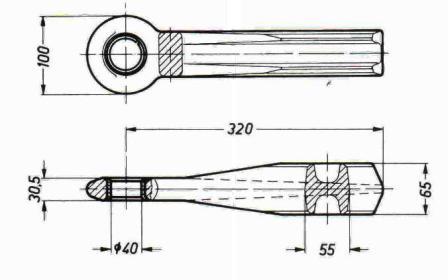

The AL03196 is a 40mm weld on road rated towing eye. This unit has a load rating of 120kN and is suitable for medium sized trailers. It is a popular choice for trucks and harvesters towing comb trailers and can be used in conjunction with our 40mm couplers shown under trailer couplings on this site.

Note: This model is supplied with a pressed in replaceable bush in the eye section.

PRODUCT SPECS & PHOTOS

| Part number | AL03196 |

| Model | ROE57374 |

| D value | 120 (kN) |

| DIN | 74054-40A |

| Eye size. ID x OD x Thickness | 40mm x 100mm x 30mm |

| Weld in body section | 65H x 57W x 125L |

| Centre of eye to weld in section | 210mm |

| Overall length | 375mm |

| Down Load | 250kg |

| CRN | 41539 |

| Weight | 5 kg |

Welding

1. On-road drawbar eyes are provided for welding into the drawbar by electric arc welding, preferably done under a protective gas shield. Welding must be performed by a person qualified to work on such equipment. Regulations may vary from state to state.

2. The steel of the drawbar has to be weldable, e.g. made of St 37-2 or St 52-3 or any other compatible weldable steel with a carbon content of less than 0.22%.

3. Remove all paint, grease and rust from welding surfaces. Heating up of drawbar eye to 200 – 250°C before beginning to weld is recommended.

4. The drawbar eye must not be welded within a length of *mm measured from the middle of the drawbar eye access towards the back. This part should protrude out of the drawbar.

5. The welding should be exercised in one seam at a time only, in order to avoid overheating the surrounding space of the welding seam.

6. Carry the welding onwards to the direction of the drawbar eye access in one procedure.

7. All seams have to be laid in longitudinal direction of the drawbar eyes shaft. Never and by no means crosswire.

8. Each seam of welding should be set one by one diagonally opposite to the last one, so you maintain an even radiation of heat.

9. Cooling down of the welding should take place where the air is still; do not immerse into water or pour water over it.

10. If wanted, you can place slot welds through the lateral surface of the drawbars sectional steel. This is in order to attach the drawbar shaft to the drawbar additionally.

11. The thickness of the welding seams is to be approximately 8mm in full V- shape or half V-shape.

12. The thickness of the sectional connecting bars should be at least 8mm, better from 10mm – 12mm.

Drawbar eyes: *

57268 DIN 65 x 55, 40mm = 210mm

57262 DIN 50 x 40, 40mm = 210mm

57260 DIN 40 x 40, 40mm = 210mm

57272 DIN + ISO 65 x 60, 50mm = 210mm

57254 Rockinger for 56, 561 and 702, 50mm = 195mm

57006 ring 41 strong, NATO, 76mm = 180mm