Home » Product Catalogue » GEARBOXES » WORM WHEEL SPEED REDUCTION BOXES » TECHNICAL INFORMATION

TECHNICAL INFORMATION

Selection

Care should be taken when selecting a Worm wheel reduction gearbox for a new application. There are many factors that can affect the service life of the unit. The correct selection must be made to ensure the efficiency of the reducer.

Some of these factors including service, load, torque etc. are shown in the following information.

Note: THESE RATINGS ARE ONLY A GUIDE. Ratings shown are compiled using standard engineering procedures. Aline Trading P/L does not guarantee ratings in specific applications. Prototype testing of every application is recommended before production.

Size

Worm wheel reduction gearboxes are made in many styles and sizes. The size of the gearbox is referred to as the “Frame Size”. The frame size is the distance measured between the centre lines of the input and output shafts in mm. This size increases with the capacity of the gearbox and is often shown on the side of the main housing as a number in raised lettering. E.G., 60.

The standard frame sizes offered in our range of single start boxes are:

40 – 50 – 60 – 70 – 80 – 100 – 120 – 135 – 155 – 175 – 200 – 250

Gear Ratio

Once the frame size has been established you must then select the gear ratio. Gear ratios offered in our range of single reduction boxes are:

5:1 – 10:1 – 15:1 – 20:1 – 25:1 – 30:1 – 40:1 – 50:1 – 60:1

These ratios are available in all frame sizes.

Larger ratios are available in the more advanced models.

Input Shaft Speed

General input shaft speed is 600-1500 RPM. The maximum is 1800 RPM.

The minimum speed of 300 RPM is shown on most charts does not illustrate the lowest recommended input speed. The unit will run efficiently at speeds down to and below 100 rpm with greatly reduced horsepower capacity. Low speeds may also affect the efficiency of lubrication.

Worm boxes are generally driven by a drive motor but can also be used with a hand drive device when required.

Output Shaft Speed

Depends on the input shaft speed and the reduction ratio.

Torque

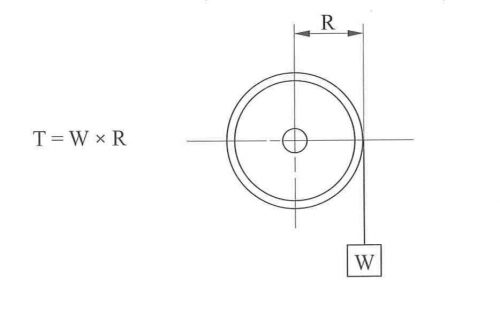

The transmission torque of the reducer depends upon the force that causes the output shaft to rotate and the rotary radius. See diagram below.

Note: Maximum momentary (starting) torque is limited to 25% of rated capacity.

Efficiency

Efficiency calculations may be made by dividing HP OUTPUT by HP INPUT.

When only the output torque and input horsepower is known, the output torque may be converted to HP by the following:

HP Output = Output Torque x RPM Output divided by 63,025

Thermal Capacity

The thermal capacity of the Aline unit = the maximum capacity that it can operate at a temp not exceeding 80 deg C. Operation over this temp will require additional cooling provisions.

A run in period of approx. 50 hours is normally required for worm type reducers.

Lubrication

The reducer should be filled with the appropriate oil to the centre of the oil gauge before putting into service.

Excessive oil levels result in higher operating temperatures and are as undesirable as using too little oil.

After approximately 85 hours of operation the reducer must be drained, flushed thoroughly with light oil and refilled with fresh recommended oil.

This flushing and refilling should be repeated every 2500 hours.

We use and recommend SAE 320 oil for most normal applications.

Overhung Load

Shaft or housing damage can be caused by excessive overhung load on the output shaft. The O.H.L should be included in calculations for new applications.

| OVERHUNG LOAD FACTOR |

|

| Type of Drive | O.H.L factor |

| Sprocket | 1.00 |

| Gear | 1.25 |

| V-Belt | 1.50 |

| Flat Belt | 2.50 |

| LOAD CLASSIFICATIONS | |

| Uniform Load | Free From Shock |

| Conveyors | Uniform Loads |

| Pumps | Centrifugal, Rotary |

| Compressors | Vane Type |

| Mixers | Constant Density |

| Moderate Shock | |

| Conveyors | Not Uniform feed |

| Pumps | Reciprocating |

| Mixers | Variable Density |

| Heavy Shock Load | Constant Shock |

| Conveyors | Not uniform feed |

| Hammer Mills | |

| Crushers | |

| SERVICE FACTORS | ||||

| Prime Mover | Duration of Service Per Day. (1) | Driven Machine Load Classification | ||

| Uniform | Medium Shock | Heavy Shock | ||

Electric Motor | Intermittent 2 hrs | 0.9 | 1.00 | 1.25 |

| Occasional 1/2 hr | 0.8 | 0.9 | 1.00 | |

| 10 hrs | 1.00 | 1.25 | 1.50 | |

| 24 hrs | 1.25 | 1.50 | 1.75 | |

Electric Motor With Frequent Starts & Stops | Intermittent 2 hrs | 1.00 | 1.25 | 1.50 |

| Occasional 1/2 hr | 0.9 | 1.00 | 1.25 | |

| 10 hrs | 1.25 | 1.50 | 1.75 | |

| 24 hrs | 1.50 | 1.75 | 2.00 | |

Multi Cylinder Combustion Engine. | Intermittent 2 hrs | 1.00 | 1.25 | 1.50 |

| Occasional 1/2 hr | 0.90 | 1.00 | 1.25 | |

| 10 hrs | 1.25 | 1.50 | 1.75 | |

| 24 hrs | 1.50 | 1.75 | 2.00 | |

Single Cylinder Combustion Engine | Intermittent 2 hrs | 1.25 | 1.15 | 1.75 |

| Occasional 1/2 hr | 1.00 | 1.25 | 1.50 | |

| 10 hr | 1.50 | 1.75 | 2.00 | |

| 24 hrs | 1.75 | 2.00 | 2.25 | |

| Note: Intermittent & occasional service refers to TOTAL operating period per day. “Frequent Start & Stops” refers to more than 10 starts per hr. | ||||

When ordering a Worm Wheel Reduction Gearbox, please specify the following:

1. Worm frame size.

2. Gear ratio.

3. Input motor information. Power, speed (RPM), type. If flange mount electric motors please specify the mount details/dimensions required.

4. Mounting arrangement required.

5. Output shaft arrangement.

Horsepower and Torque Rating Tables

These figures are indicative for standard worm drive boxes like FCA or FCWA models and reflect conditions under perfect drive. Refer to the factor chart for various applications.

Based on a Duty Cycle of 8-10 hours per day continuous.

Torque is in kg-Metres

OHL is Overhung Load in Kgs.

| SIZE | RATIO | 10:1 | |||||

| INPUT RPM | 1800 | 1500 | 1200 | 900 | 600 | 300 | |

| 50 | INPUT HP | 1.23 | 1.16 | 1.01 | .86 | .58 | .31 |

| OUTPUT HP | .99 | .93 | .84 | .67 | 045 | .23 | |

| OUTPUT TORQUE kg-m | 3.95 | 4.47 | 4.80 | 5.33 | 5.43 | 5.43 | |

| OUTPUT OHL kg | 90 | 100 | 110 | 120 | 140 | 200 | |

| 60 | INPUT HP | 2.52 | 2.01 | 1.76 | 1.52 | 1.19 | .64 |

| OUTPUT HP | 1.78 | 1.63 | 1.41 | 1.20 | .92 | .48 | |

| OUTPUT TORQUE kg-m | 7.09 | 7.82 | 8.45 | 9.62 | 11 | 11.6 | |

| OUTPUT OHL kg | 90 | 100 | 110 | 120 | 140 | 200 | |

| 70 | INPUT HP | 3.27 | 3.01 | 2.68 | 2.24 | 1.75 | 1.15 |

| OUTPUT HP | 2.69 | 2.45 | 2.16 | 1.79 | 1.36 | .86 | |

| OUTPUT TORQUE kg-M | 10.7 | 11.7 | 12.9 | 14.3 | 16.3 | 20.7 | |

| OUTPUT OHL kg | 140 | 150 | 160 | 170 | 200 | 300 | |

| 80 | INPUT HP | 4.50 | 4.36 | 3.81 | 3.20 | 2.57 | 1.56 |

| OUTPUT HP | 3.27 | 3.55 | 3.08 | 2.56 | 2.01 | 1.18 | |

| OUTPUT TORQUE kg-m | 14.8 | 17.0 | 18.4 | 20.5 | 24.0 | 28.3 | |

| OUTPUT OHL kg | 160 | 180 | 200 | 230 | 270 | 400 | |

| 100 | INPUT HP | 6.50 | 5.98 | 5.26 | 4.49 | 3.51 | 2.27 |

| OUTPUT HP | 5.37 | 4.90 | 4.30 | 3.64 | 2.78 | 1.74 | |

| OUTPUT TORQUE kg-m | 21.4 | 23.4 | 25.7 | 29.0 | 33.2 | 41.5 | |

| OUTPUT OHL kg | 190 | 200 | 220 | 240 | 300 | 440 | |

| 120 | INPUT HP | 10.7 | 10.1 | 8.58 | 7.40 | 5.75 | 3.74 |

| OUTPUT HP | 8.89 | 8.35 | 7.03 | 6.01 | 4.60 | 2.89 | |

| OUTPUT TORQUE kg-m | 35.4 | 39.9 | 42.0 | 47.9 | 55.0 | 69.1 | |

| OUTPUT OHL kg | 250 | 260 | 280 | 300 | 350 | 520 | |

| 135 | INPUT HP | 17.7 | 16.5 | 14.2 | 12.0 | 9.54 | 6.20 |

| OUTPUT HP | 15.0 | 13.9 | 11.9 | 10.0 | 7.83 | 4.94 | |

| OUTPUT TORQUE kg-m | 59.7 | 66.4 | 71.0 | 79.6 | 93.5 | 117 | |

| OUTPUT OHL kg | 330 | 340 | 360 | 440 | 500 | 800 | |

| SIZE | RATIO | 20:1 | |||||

| INPUT RPM | 1800 | 1500 | 1200 | 900 | 600 | 300 | |

| 50 | INPUT HP | 0.71 | 0.63 | 0.55 | 0.48 | 0.35 | 0.17 |

| OUTPUT HP | 0.50 | 0.44 | 0.38 | 0.32 | 0.23 | 0.11 | |

| OUTPUT TORQUE kg-m | 4.00 | 4.25 | 4.58 | 5.07 | 5.43 | 5.43 | |

| OUTPUT OHL kg | 130 | 140 | 155 | 170 | 200 | 200 | |

| 60 | INPUT HP | 1.18 | 1.06 | 0.95 | 0.79 | 0.64 | 0.37 |

| OUTPUT HP | 0.89 | 0.79 | 0.69 | 0.57 | 0.44 | 0.24 | |

| OUTPUT TORQUE kg-m | 7.09 | 7.58 | 8.20 | 9.00 | 10.4 | 11.6 | |

| OUTPUT OHL kg | 130 | 140 | 155 | 170 | 200 | 200 | |

| 70 | INPUT HP | 1.83 | 1.66 | 1.44 | 1.17 | 0.86 | 0.50 |

| OUTPUT HP | 1.42 | 1.27 | 1.09 | 0.87 | 0.62 | 0.34 | |

| OUTPUT TORQUE kg-M | 11.3 | 12.1 | 13.0 | 13.9 | 14.7 | 16.0 | |

| OUTPUT OHL kg | 210 | 230 | 250 | 270 | 300 | 300 | |

| 80 | INPUT HP | 2.48 | 2.25 | 1.97 | 1.65 | 1.32 | 0.87 |

| OUTPUT HP | 1.91 | 1.71 | 1.47 | 1.21 | 0.93 | 0.57 | |

| OUTPUT TORQUE kg-m | 15.2 | 16.3 | 17.5 | 19.2 | 22.3 | 27.3 | |

| OUTPUT OHL kg | 270 | 280 | 320 | 360 | 400 | 400 | |

| 100 | INPUT HP | 4.42 | 3.99 | 3.48 | 2.92 | 2.31 | 1.51 |

| OUTPUT HP | 3.52 | 3.14 | 2.71 | 2.23 | 1.73 | 1.06 | |

| OUTPUT TORQUE kg-m | 28.0 | 30.0 | 32.3 | 35.5 | 41.3 | 50.0 | |

| OUTPUT OHL kg | 250 | 270 | 300 | 340 | 450 | 450 | |

| 120 | INPUT HP | 6.85 | 6.31 | 5.53 | 4.68 | 3.70 | 1.95 |

| OUTPUT HP | 5.40 | 4.92 | 4.26 | 3.53 | 2.71 | 1.68 | |

| OUTPUT TORQUE kg-m | 43.0 | 47.0 | 50.9 | 56.2 | 64.6 | 80.0 | |

| OUTPUT OHL kg | 370 | 390 | 420 | 460 | 520 | 520 | |

| 135 | INPUT HP | 10.3 | 9.26 | 8.14 | 6.79 | 5.36 | 3.47 |

| OUTPUT HP | 8.39 | 7.47 | 6.48 | 5.33 | 4.13 | 2.54 | |

| OUTPUT TORQUE kg-m | 66.8 | 71.3 | 77.4 | 84.9 | 98.6 | 121 | |

| OUTPUT OHL kg | 570 | 600 | 660 | 760 | 810 | 810 | |

| SIZE | RATIO | 30:1 | |||||

| INPUT RPM | 1800 | 1500 | 1200 | 900 | 600 | 300 | |

| 50 | INPUT HP | 0.62 | 0.55 | 0.45 | 0.36 | 0.25 | 0.13 |

| OUTPUT HP | 0.42 | 0.37 | 0.30 | 0.23 | 0.16 | 0.08 | |

| OUTPUT TORQUE kg-m | 5.02 | 5.31 | 5.43 | 5.49 | 5.43 | 5.43 | |

| OUTPUT OHL kg | 150 | 170 | 180 | 200 | 200 | 200 | |

| 60 | INPUT HP | 1.07 | 0.98 | 0.87 | 0.74 | 0.52 | 0.28 |

| OUTPUT HP | 0.75 | 0.67 | 0.58 | 0.48 | 0.32 | 0.16 | |

| OUTPUT TORQUE kg-m | 9.0 | 9.60 | 10.3 | 11.15 | 11.6 | 11.6 | |

| OUTPUT OHL kg | 150 | 170 | 180 | 200 | 200 | 200 | |

| 70 | INPUT HP | 1.56 | 1.41 | 1.26 | 1.06 | 0.85 | 0.43 |

| OUTPUT HP | 1.12 | 0.98 | 0.85 | 0.71 | 0.53 | 0.29 | |

| OUTPUT TORQUE kg-M | 13.4 | 14.2 | 15.2 | 17.0 | 19.0 | 20.5 | |

| OUTPUT OHL kg | 240 | 260 | 280 | 300 | 300 | 300 | |

| 80 | INPUT HP | 2.09 | 1.90 | 1.65 | 1.43 | 1.14 | 0.75 |

| OUTPUT HP | 1.51 | 1.34 | 1.14 | 0.96 | 0.73 | 0.44 | |

| OUTPUT TORQUE kg-m | 18.1 | 19.2 | 20.5 | 22.9 | 26.2 | 31.4 | |

| OUTPUT OHL kg | 320 | 340 | 360 | 400 | 400 | 400 | |

| 100 | INPUT HP | 3.69 | 3.33 | 2.93 | 2.47 | 1.97 | 1.15 |

| OUTPUT HP | 2.70 | 2.40 | 2.06 | 1.71 | 1.30 | 0.70 | |

| OUTPUT TORQUE kg-m | 32.2 | 34.4 | 36.9 | 40.8 | 46.8 | 50.0 | |

| OUTPUT OHL kg | 320 | 340 | 370 | 450 | 450 | 450 | |

| 120 | INPUT HP | 6.27 | 5.68 | 5.00 | 4.18 | 3.39 | 1.89 |

| OUTPUT HP | 4.64 | 4.15 | 3.59 | 2.92 | 2.27 | 1.17 | |

| OUTPUT TORQUE kg-m | 55.4 | 59.4 | 64.3 | 69.8 | 81.4 | 84.0 | |

| OUTPUT OHL kg | 450 | 470 | 500 | 520 | 520 | 520 | |

| 135 | INPUT HP | 8.76 | 7.87 | 6.86 | 5.82 | 4.64 | 3.02 |

| OUTPUT HP | 6.65 | 5.90 | 5.07 | 4.20 | 3.23 | 1.96 | |

| OUTPUT TORQUE kg-m | 79.4 | 84.5 | 90.8 | 100 | 116 | 140 | |

| OUTPUT OHL kg | 680 | 710 | 710 | 810 | 810 | 810 | |

| SIZE | RATIO | 40:1 | |||||

| INPUT RPM | 1800 | 1500 | 1200 | 900 | 600 | 300 | |

| 50 | INPUT HP | 0.47 | 0.43 | 0.39 | 0.32 | 0.22 | 0.11 |

| OUTPUT HP | 0.028 | 0.25 | 0.22 | 0.17 | 0.12 | 0.06 | |

| OUTPUT TORQUE kg-m | 4.53 | 4.82 | 5.41 | 5.43 | 5.43 | 5.43 | |

| OUTPUT OHL kg | 170 | 180 | 200 | 200 | 200 | 200 | |

| 60 | INPUT HP | 0.78 | 0.71 | 0.64 | 0.54 | 0.43 | 0.24 |

| OUTPUT HP | 0.51 | 0.45 | 0.39 | 0.32 | 0.24 | 0.12 | |

| OUTPUT TORQUE kg-m | 8.06 | 8.60 | 9.20 | 10.3 | 11.5 | 11.6 | |

| OUTPUT OHL kg | 170 | 180 | 200 | 200 | 200 | 200 | |

| 70 | INPUT HP | 1.18 | 1.07 | 0.94 | 0.77 | 0.56 | 0.33 |

| OUTPUT HP | 0.81 | 0.72 | 0.62 | 0.49 | 0.34 | 0.18 | |

| OUTPUT TORQUE kg-M | 12.9 | 13.7 | 14.8 | 15.5 | 16.2 | 17.4 | |

| OUTPUT OHL kg | 270 | 280 | 300 | 300 | 300 | 300 | |

| 80 | INPUT HP | 1.60 | 1.47 | 1.29 | 1.10 | 0.86 | 0.54 |

| OUTPUT HP | 1.08 | 0.96 | 0.83 | 0.68 | 0.52 | 0.30 | |

| OUTPUT TORQUE kg-m | 17.2 | 18.3 | 19.7 | 21.8 | 24.7 | 28.0 | |

| OUTPUT OHL kg | 340 | 360 | 400 | 400 | 400 | 400 | |

| 100 | INPUT HP | 2.78 | 2.52 | 2.20 | 1.88 | 1.48 | 0.89 |

| OUTPUT HP | 2.00 | 1.77 | 1.52 | 1.26 | 0.96 | 0.52 | |

| OUTPUT TORQUE kg-m | 31.8 | 33.8 | 36.3 | 40.2 | 45.7 | 50.0 | |

| OUTPUT OHL kg | 350 | 380 | 450 | 450 | 450 | 450 | |

| 120 | INPUT HP | 4.48 | 4.07 | 3.56 | 3.03 | 2.44 | 1.57 |

| OUTPUT HP | 3.13 | 2.79 | 2.99 | 1.97 | 1.51 | 0.88 | |

| OUTPUT TORQUE kg-m | 49.8 | 53.2 | 57.1 | 62.8 | 72.2 | 84.0 | |

| OUTPUT OHL kg | 500 | 500 | 520 | 520 | 520 | 520 | |

| 135 | INPUT HP | 6.44 | 5.74 | 5.06 | 4.38 | 3.40 | 2.18 |

| OUTPUT HP | 4.79 | 4.22 | 3.64 | 3.06 | 2.31 | 1.36 | |

| OUTPUT TORQUE kg-m | 76.3 | 80.7 | 86.9 | 97.4 | 110 | 130 | |

| OUTPUT OHL kg | 710 | 770 | 810 | 810 | 810 | 810 | |

| SIZE | RATIO | 50:1 | |||||

| INPUT RPM | 1800 | 1500 | 1200 | 900 | 600 | 300 | |

| 50 | INPUT HP | 0.39 | 0.37 | 0.31 | 0.26 | 0.18 | 0.09 |

| OUTPUT HP | 0.23 | 0.21 | 0.17 | 0.14 | 0.09 | 0.04 | |

| OUTPUT TORQUE kg-m | 4.62 | 4.91 | 5.19 | 5.43 | 5.43 | 5.43 | |

| OUTPUT OHL kg | 200 | 200 | 206 | 200 | 200 | 200 | |

| 60 | INPUT HP | 0.61 | 0.55 | 0.51 | 0.43 | 0.35 | 0.20 |

| OUTPUT HP | 0.36 | 0.32 | 0.28 | 0.23 | 0.17 | 0.09 | |

| OUTPUT TORQUE kg-m | 7.10 | 7.60 | 8.30 | 9.10 | 10.2 | 11.6 | |

| OUTPUT OHL kg | 180 | 200 | 200 | 200 | 200 | 200 | |

| 70 | INPUT HP | 0.87 | 0.79 | 0.71 | 0.61 | 0.50 | 0.30 |

| OUTPUT HP | 0.52 | 0.46 | 0.40 | 0.33 | 0.25 | 0.15 | |

| OUTPUT TORQUE kg-M | 10.4 | 11.0 | 11.9 | 13.1 | 14.8 | 17.4 | |

| OUTPUT OHL kg | 280 | 300 | 300 | 300 | 300 | 300 | |

| 80 | INPUT HP | 1.28 | 1.17 | 1.05 | 0.88 | 0.72 | 0.45 |

| OUTPUT HP | 0.84 | 0.75 | 0.65 | 0.53 | 0.40 | 0.23 | |

| OUTPUT TORQUE kg-m | 16.8 | 17.8 | 19.3 | 21.2 | 23.9 | 28.0 | |

| OUTPUT OHL kg | 360 | 400 | 400 | 400 | 400 | 400 | |

| 100 | INPUT HP | 2.78 | 2.52 | 2.20 | 1.88 | 1.48 | 0.89 |

| OUTPUT HP | 2.00 | 1.77 | 1.52 | 1.26 | 0.96 | 0.52 | |

| OUTPUT TORQUE kg-m | 31.8 | 33.8 | 36.3 | 40.2 | 45.7 | 50.0 | |

| OUTPUT OHL kg | 350 | 380 | 450 | 450 | 450 | 450 | |

| 120 | INPUT HP | 3.64 | 3.28 | 2.90 | 2.47 | 1.91 | 1.19 |

| OUTPUT HP | 2.61 | 2.31 | 2.01 | 1.66 | 1.24 | 0.70 | |

| OUTPUT TORQUE kg-m | 52.0 | 55.2 | 60.1 | 66.0 | 74.2 | 84.0 | |

| OUTPUT OHL kg | 500 | 520 | 520 | 520 | 520 | 520 | |

| 135 | INPUT HP | 4.84 | 4.41 | 3.90 | 3.34 | 2.61 | 1.69 |

| OUTPUT HP | 3.52 | 3.16 | 2.73 | 2.26 | 1.71 | 1.01 | |

| OUTPUT TORQUE kg-m | 70.0 | 75.5 | 81.4 | 90.1 | 102 | 120 | |

| OUTPUT OHL kg | 770 | 810 | 810 | 810 | 810 | 810 | |

| SIZE | RATIO | 60:1 | |||||

| INPUT RPM | 1800 | 1500 | 1200 | 900 | 600 | 300 | |

| 50 | INPUT HP | 0.33 | 0.30 | 0.26 | 0.23 | 0.15 | 0.07 |

| OUTPUT HP | 0.18 | 0.16 | 0.13 | 0.11 | 0.07 | 0.03 | |

| OUTPUT TORQUE kg-m | 4.31 | 4.61 | 4.83 | 5.41 | 5.43 | 5.43 | |

| OUTPUT OHL kg | 200 | 200 | 200 | 200 | 200 | 200 | |

| 60 | INPUT HP | 0.51 | 0.47 | 0.42 | 0.35 | 0.29 | 0.19 |

| OUTPUT HP | 0.29 | 0.26 | 0.22 | 0.18 | 0.14 | 0.08 | |

| OUTPUT TORQUE kg-m | 6.90 | 7.40 | 8.00 | 8.70 | 9.70 | 11.3 | |

| OUTPUT OHL kg | 200 | 200 | 200 | 200 | 200 | 200 | |

| 70 | INPUT HP | 0.75 | 0.68 | 0.63 | 0.51 | 0.43 | 0.28 |

| OUTPUT HP | 0.44 | 0.39 | 0.34 | 0.27 | 0.21 | 0.12 | |

| OUTPUT TORQUE kg-M | 10.4 | 11.1 | 12.0 | 13.1 | 14.7 | 17.1 | |

| OUTPUT OHL kg | 300 | 300 | 300 | 300 | 300 | 300 | |

| 80 | INPUT HP | 1.03 | 0.95 | 0.85 | 0.73 | 0.58 | 0.39 |

| OUTPUT HP | 0.62 | 0.55 | 0.48 | 0.39 | 0.29 | 0.17 | |

| OUTPUT TORQUE kg-m | 14.9 | 15.7 | 17.2 | 18.7 | 21.0 | 24.6 | |

| OUTPUT OHL kg | 400 | 400 | 400 | 400 | 400 | 400 | |

| 100 | INPUT HP | 1.87 | 1.70 | 1.53 | 1.28 | 1.02 | 0.65 |

| OUTPUT HP | 1.26 | 1.12 | 0.97 | 0.80 | 0.59 | 0.34 | |

| OUTPUT TORQUE kg-m | 30.0 | 32.0 | 34.6 | 38.0 | 42.4 | 49.3 | |

| OUTPUT OHL kg | 400 | 450 | 450 | 450 | 450 | 450 | |

| 120 | INPUT HP | 2.89 | 2.65 | 2.36 | 2.04 | 1.45 | 0.96 |

| OUTPUT HP | 1.98 | 1.76 | 1.53 | 1.26 | 0.94 | 0.56 | |

| OUTPUT TORQUE kg-m | 47.4 | 50.4 | 54.9 | 60.1 | 67.6 | 80.0 | |

| OUTPUT OHL kg | 520 | 520 | 520 | 520 | 520 | 520 | |

| 135 | INPUT HP | 3.65 | 3.58 | 3.16 | 2.74 | 2.11 | 1.37 |

| OUTPUT HP | 2.55 | 2.40 | 2.12 | 1.76 | 1.32 | 0.77 | |

| OUTPUT TORQUE kg-m | 60.8 | 70.0 | 76.0 | 83.9 | 94.4 | 111 | |

| OUTPUT OHL kg | 810 | 810 | 810 | 810 | 810 | 810 | |